Cattle Feed & Polutry Feed Plant

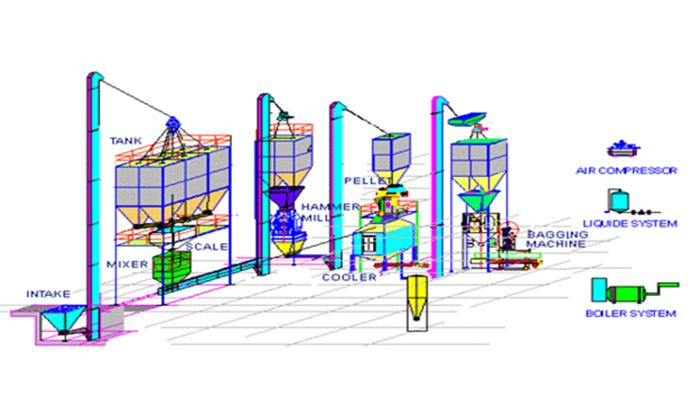

Our cattle feed manufacturing plant comprises of complete process ranging from disintegrating to mixing up to palletizing. This makes the feed easy to eat for the cattle. Widely demanded in cattle feed industry, these plants are capable of mixing various ingredients uniformly for making proper feed.

Hammer Mill

Hammer Mill ensure proper palletizing by disintegrating the products into a desired size for uniform mixing and excellent quality cattle feed.

- • Ensures uniform mixing

- • Excellent quality cattle feed

- • Proper disintegration into a desired size

Mixture Machine

Mixture Machine uses the principle of batch system for mixing different ingredients of the cattle feeds. Constructed with a strong body and integrated with built in reduction gear box, the mixture machine is quite easy to operate with manually operated feeding system. This ensures even mixing of different ingredients of cattle feed plant.

- • It is featured with strong body

- • Integrated with built in reduction gear box

- • Manual feeding system for even mixing

Pellet Machine

Pellet Machine is engineered and developed for making pellets of cattle feed, depending on the size required so that it becomes easy to eat for cattle.

>- • Easy maintenance

- • High quality materials

- • Easy to operate

- • Precise operation

Hopper For Mixture

Sturdy in construction and easy in maintenance, Hopper is specially designed and installed for easy traveling of material to mixture and also serves as the storage space for materials of the next batch.

- • Sturdy construction

- • Easy maintenance

- • Easy traveling of materials and storage

POULTRY FEED PLANT

Poultry feed plant has a number of applications which are dependent on a number of things. They are used as multi-purpose. They are suitable for making various types of poultry feeds and aquatic feeds. They also provide a wide range of diameters starting from 2-10mm depending on the type of animal.

The process of poultry feed production is generally divided into the following steps:

- 1) Feed raw materials receiving and cleaning

- 2) Raw materials crushing

- 3) Batching

- 4) Mixing

- 5) Pelleting

- 6) Packaging of finished feed products.

Pellet Cooler

Pellet Cooler is used to cool down the cattle feed for a safe storage and packing. It ensures even cooling in less time.

- • Even cooling

- • Less time required

- • Low power consumption